KYLE MEINERT

KYLE MEINERT

HNI Risk Advisor

When I take on new health and safety advisory clients, one of my first tasks is auditing their workplace safety manual.

And let me tell you, folks, I've seen the good, the bad, and the ugly when it comes to these documents!

Some workplace safety manuals have been handwritten in pencil.

Some workplace safety manuals have been collecting dust since 1970 (that's when the Occupational Safety and Health Administration was founded).

Some workplace safety manuals never have been liberated from the plastic bag they came in.

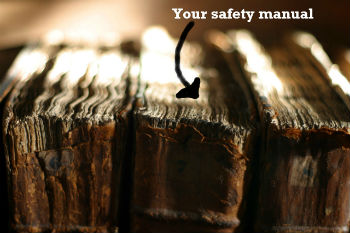

No matter the condition of your workplace safety manual, at some point someone thought investing in this document was a good idea. So what causes this safety “bible” to be forgotten, when most likely it has some great, lifesaving policies inside, not to mention that it also contains safety policies that are required to be in written format by the people at OSHA?

The No. 1 answer I've heard to this question is (you guessed it): "No one reads it anyway.” The No. 2 response is: “We have a safety manual?”

So how do we fix this issue? Let's drill down into what's really going on, starting with "The Ugly":

The Ugly: The Behemoth that No One Reads

Look at your current safety manual. If it's so big that it requires its own ZIP code, we have an uphill battle ahead of us. For every 10 safety manuals that I dig into, eight of them wouldn’t fit into a standard three-ring binder.

There is a common misconception that bigger is better. But is it? What good is a safety manual that’s 600 pages, covers all your safety policies — covers every safety policy ever created — and the only page your employees look at is the one with the pivotal line for "Sign here if you read this encyclopedia and turn into the HR director/safety person"?

Not only does this mammoth safety manual have boilerplate policies that don't address your specific work environment, but you're also opening yourself up to situations that really can cost you.

Picture this (and it's not a stretch): An employer has a written hazard policy to protect employees, but this policy isn’t known because it's buried in a giant manual. Suppose a worker gets injured because this policy wasn’t enforced. What message does this send to the compliance safety and health officer who shows up at your door? Not a very good one!

The Bad: The Canned Manual that Doesn't Deliver

I just touched on this next topic: the importance of customization. Buying a “canned” safety manual that that covers every safety situation under the sun is not be the best option, either.

A workplace safety manual publisher just can't know the ins and outs of your unique business. Letting a publisher set your standard of safety is like to going out for 18 holes on Pebble Beach with nothing but a pitching wedge.

The truth is, no one knows the true hazards of a work environment like the people who actually work in the environment. They need to get engaged in making sure your manual reflects the realities of your workplace.

The Good: Cuts to the Chase for Your Workplace

When it comes to a quality safety manual, the cliche “You get what you put into it” rings true.

It will take days to really step back and think about what you want your safety message to be. Spending loads of cash on a canned manual will give you a quick fix but leave you with a square peg in a round hole.

Your workplace safety manual must be detailed to the point that it works for your specific environment, but not to the point that the message soars over everyone’s heads. Too much information will drown out what's really important!

Additionally, only include what is actually needed into these manuals. If you can name someone who would enjoy reading a 600-page safety manual, then you also can name someone who probably needs a new hobby!

Take out the filler and the fluff. Refine your manual to the valuable information that boldly and effectively transmits your safety message, a message that your people can practice every day.

Over to you: How have you optimized your workplace safety manual? How did you engage your people in making sure it works for your environment? Please share best practices in comments!

Related Posts:

The Safety G A P: Is Anything Falling Through the Cracks?

Your Company's 5-Point Plan of Attack for Total Risk Management

So You Had a Trucking Accident: Who Needs to be Ready to Respond?

4 Key Takeaways from Our Hazcom and GHS Training Webinar

.png?width=69&height=53&name=Acrisure%20Logo%20(White%20Horizontal).png)

![[ WATCH THE WEBINAR ] Safety Basics for the Non-Safety Professional](https://no-cache.hubspot.com/cta/default/38664/f557daf4-f180-4e19-b4e9-64cdce0ef198.png)